Using International “Best Tested and Proven”

Practice for the Boiler Project

FEATURED PAPER

By Umar Heru Setiadi

Balikpapan, Indonesia

ABSTRACT

National Oil Company plans to build several oil refinery development projects in Indonesia to meet domestic fuel demand. One of the facilities to be built is a Boiler Unit to produce steam and power. The objective of this paper is to improve the Front-End Loading Phase by preparing a standardized WBS Structure and Bidding Template for the New Boiler project. The Methodology involves the use of “Best Tested and Proven” Practice in preparing the WBS Structure and Bidding Template as the Company’s new standard. The study concludes that the ideal choice for the Standardized WBS Structure is to adopt the Omniclass Table because it offers significant advantages in terms of standardization, efficiency, data management, and project control. Meanwhile, the US-National Park Service Class A Cost Estimate Template is an ideal choice to be adopted as a standardized Bidding Template because it offers precise, comprehensive, and standardized cost data. By having the best standards, it can significantly improve project management, reduce cost overruns, achieve project schedule and in the future can be integrated with BIM technology.

Keywords: Work Breakdown Structure, WBS, Boiler, Omniclass, Building Information Modeling, BIM, Oil Refinery, National Park Service, NPS, Bidding Template, Decision Support Package, Cost Estimate, Front-End Loading, National Oil Company

INTRODUCTION

- The Needs of The Oil Refinery Development Projects in Indonesia

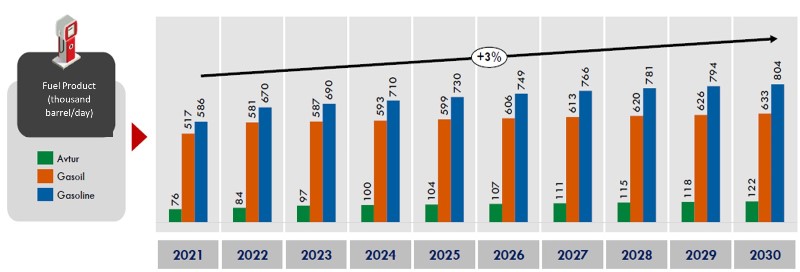

The trend of fuel oil demand in Indonesia continues to increase by 3% per year and is predicted to reach 1.5 million barrels/day in 2030. Meanwhile, the existing oil refinery owned by the National Oil Company can only produce around 729 thousand barrels daily. Therefore, Indonesia must meet domestic needs through imports. This condition will undoubtedly affect Indonesia’s state finances. Hence, through its National Oil Company, Indonesia plans to increase the production capacity of oil refineries to meet domestic fuel needs by building new and expanding the capacity of existing oil refineries through the Refinery Development Masterplan (RDMP) program.

The trend of demand for fuel oil in Indonesia continues to increase, as per the figure below:

Figure 1. The Trend of Domestic Demand for Fuel Products [1]

According to the Roadmap for Oil Refinery Development by National Oil Company throughout Indonesia (Figure 2), NOC plans to increase the national oil refinery production capacity through 10 Existing Oil Refinery Development Projects (RDMP) and four new oil and petrochemical refinery development projects (grass root refinery) (blue color).

More…

To read entire paper, click here

Editor’s note: This paper was originally prepared during a 6-month long Graduate-Level Competency Development/Capacity Building Program developed by PT Mitrata Citragraha and led by Dr. Paul D. Giammalvo to prepare candidates for AACE CCP or other Certifications. https://build-project-management-competency.com/our-faqs/

How to cite this paper: Setiadi, U. H. (2024). Developing a Standardized WBS and Bidding Template Using International “Best Tested and Proven” Practice for the Boiler Project; PM World Journal, Vol. XIII, Issue XI, December. Available online at https://pmworldlibrary.net/wp-content/uploads/2024/12/pmwj147-Dec2024-Setiadi-standardized-wbs-and-bidding-template-for-boiler-project.pdf

About the Author

Umar Heru Setiadi

Balikpapan, Indonesia

![]()

Umar Heru Setiadi is a project management professional with fifteen years of professional experience in the oil and gas sectors. Currently, he works as a Project Interface & Integration Manager at the national oil company of Indonesia. Several projects have been completed, such as Open Access project of Refinery Unit (RU) II Dumai, RDMP RU V Balikpapan Revamping project, Site Development & New Construction Jetty project, and other downstream projects. He holds a bachelor’s degree in chemical engineering from Gadjah Mada University (UGM) and an MBA from SBM Bandung Institute of Technology (ITB). He is attending a distance learning mentoring course, under the tutorage of Dr. Paul D. Giammalvo, CDT, CCE, MScPM, MRICS, GPM-m Senior Technical Advisor, PT Mitrata Citragraha, to attain Certified Cost Professional certification from AACE International. Umar lives in Balikpapan, Indonesia and can be contacted at umarheru@gmail.com

[1] Pertamina Energy Institute. (2022, July 22). Pertamina Energy Outlook 2021, A Perspective to 2060. Pertamina. Retrieved August 28, 2024, from: https://www.pertamina.com/id/digital-media/pertamina-energy-institute