Developing standardized Multidimensional WBS

as the Basis for Standardizing Bidding Documents

and Database Automation

FEATURED PAPER

By Arief Budi Mulyawan

Jakarta, Indonesia

ABSTRACT

As Indonesia’s total oil consumption is reaching more than 35 billion Liters in 2022 and the pipeline facilities are insufficient, the National Oil & Gas Company needs to construct additional oil pipeline facilities to overcome this. The objective of this paper is to resolve the broken Front-End Loading (FEL) Phase, which is over budget and project delay due to scope change, by implementing a standardized Multi-Dimensional, similar to the Tesseract model, Work Breakdown Structure (WBS) for oil pipeline projects using the OmniClass Coding Structure (OCCS). This standardized multi-dimensional WBS aimed to become the basis for accurate cost estimation, ease of allocating the budget, and optimal resource allocation, including ease of scheduling. This study analyzed some WBS coding structures using the Multi-Attribute Decision Making (MADM) method and obtained that OCCS can cover all criteria in the oil pipeline project WBS for building the Multi-Dimensional WBS. This study concludes that the standardized Multi-Dimensional WBS for oil pipeline projects can fulfill the stakeholders’ needs to integrate with Building Information Modeling (BIM) technologies.

Keywords: Work Breakdown Structure, WBS, Multi-Dimensional, Oil Pipeline Project, Omniclass, ISO1908:2016, Artificial Intelligence, Building Information Modelling (BIM), Multi-Attribute Decision Making (MADM), Front-End Loading, Virtual, Augmented, Mixed Reality, National Oil and Gas Company

INTRODUCTION

- The Needs of Oil Pipeline Investment

Indonesia is the fourth most populous country in the world, with a projected population of 270 million.[1]. In addition, Indonesia is an archipelago with a total area of 1.9 million square kilometers[2], and is the 15th largest country in the world by area. With such a large population, oil and gas remain the most consumed energy in various sectors, with total consumption in 2022 reaching 477.82 million barrels of oil equivalent (BOE)[3].

Highly challenging in the oil and gas industry, particularly in the downstream sector, is transporting oil from refineries to fuel terminals or between different terminals. Companies worldwide typically use various transportation methods, including oil tankers, railways, trucks, and pipelines. In the United States, “crude oil and petroleum products, according to Forbes, are shipped via 70% by pipeline, 23% by tankers and barges over water, 4% by trucks and 3% by rail.”[4].

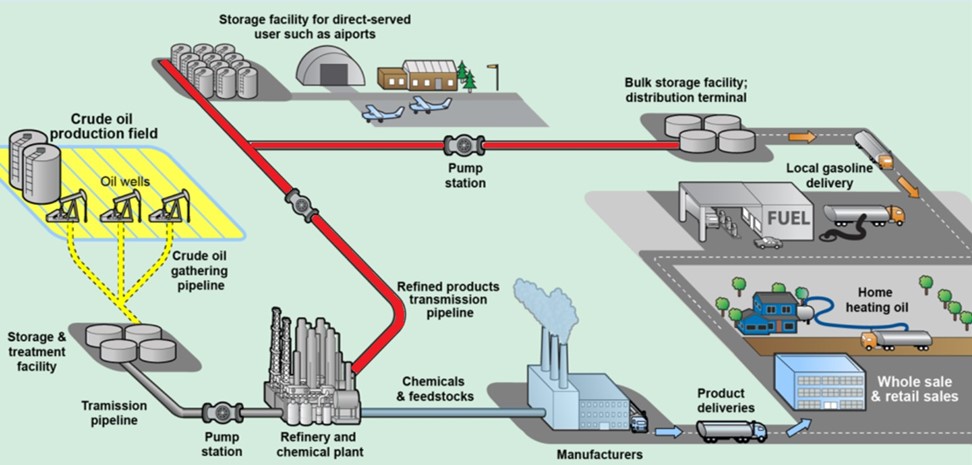

Figure 1 Illustration of Pipeline in Oil and Gas Business[5] (Red Highlight Illustrate the Pipeline used in Pertamina Patra Niaga)

Pipelines offer several benefits as a mode of transportation, with the primary advantage being “the shipping volume is large; small footprint; short construction period and low cost; safe, reliable and continuous; and consume less energy.”[6]. In addition, using pipelines also reduces transportation costs because of lower energy use and is environmentally friendly, according to IFS, LLC.[7]. In line with this, the need for oil pipelines in the National Oil Company is also increasing. With the total volume of Oil transported in 2022 reaching more than 35 billion Liters, National Oil Company currently has 1,283 kilometers of pipeline.[8][9], and aims to increase that to more than double by 2030[10].

More…

To read entire paper, click here

Editor’s note: This paper was originally prepared during a 6-month long Graduate-Level Competency Development/Capacity Building Program developed by PT Mitrata Citragraha and led by Dr. Paul D. Giammalvo to prepare candidates for AACE CCP or other Certifications. https://build-project-management-competency.com/our-faqs/

How to cite this paper: Mulyawan, A. B. (2024). A Multidimensional WBS for Oil Pipeline Project : Developing standardized Multidimensional WBS as the Basis for Standardizing Bidding Documents and Database Automation; PM World Journal, Vol. XIII, Issue X, October/November. Available online at https://pmworldlibrary.net/wp-content/uploads/2024/12/pmwj146-OctNov2024-Mulyawan-multidimensional-wbs-for-oil-pipeline-project-2.1.pdf

About the Author

Arief Budi Mulyawan

Jakarta, Indonesia

![]()

Arief Budi Mulyawan is a project engineer at the National Oil & Gas Company of Indonesia, with more than nine years of professional expertise in the oil & gas sectors. Additionally, he has served as an engineer for downstream oil and gas projects and contributed as an engineer on pier, storage tank, piping, pump, and other downstream projects across numerous provinces in Indonesia. He holds a bachelor’s and master’s degree in electrical engineering from Gadjah Mada University (UGM). Currently, he is attending a distance learning course led by Dr. Paul D. Giammalvo, CDT, CCE, MScPM, MRICS, GPM-m Senior Technical Advisor at PT Mitrata Citragraha, to obtain Certified Cost Professional certification from AACE International.

Arief Budi Mulyawan resides in Jakarta, Indonesia, and his email address is arief.abm@gmail.com.

[1] Badan Pusat Statistik. (2021). Hasil Sensus Penduduk 2020.

[2] Ibid

[3] Ministry of Energy and Mineral Resources Republic of Indonesia. (2023). Handbook of Energy & Economic Statistics of Indonesia.

[4] GeoCorr Content Team. (2021, October 29). Pipelines are the Cleanest, Safest Way to Ship Oil and Gas. https://blog.geocorr.com/pipelines-are-the-cleanest-safest-way-to-ship-oil-and-gas

[5] Avante International Technology, Inc. (2023, April 7). Pipeline integrity monitoring system (PIMS) for oil and gas transmission. https://www.avantetech.com/avante-pipeline-integrity-monitoring-system-pims-for-oil-and-gas-transmission

[6] Nan Steel. (n.d.). Advantages and disadvantages of pipeline transportation. Retrieved January 3, 2024, from https://www.nan-steel.com/news/Advantages-and-disadvantages-of-pipeline-transport.html

[7] IFS, LLC. (2019, October 22). Features/Benefits of pipeline transportation – Why pipelines are needed. Integrated Flow Solutions. https://ifsolutions.com/features-benefits-of-pipeline-transportation-why-pipelines-needed/

[8] Ministry of Energy and Mineral Resources Republic of Indonesia. (2016, March 12). Pertamina Segera Bangun Pipa BBM Sepanjang 956 Km. https://www.esdm.go.id/en/media-center/news-archives/pertamina-segera-bangun-pipa-bbm-sepanjang-956-km

[9] Jati, G. P. (2016, March 13). Pertamina Bangun pipa BBM 956 km Di Jawa Mulai Tahun Ini. Ekonomi. https://www.cnnindonesia.com/ekonomi/20160312181849-85-116935/pertamina-bangun-pipa-bbm-956-km-di-jawa-mulai-tahun-ini

[10] Task Force Roadmap Infrastruktur – PT Pertamina Patra Niaga. (2022). Roadmap PIIM (Pertamina Integrated Infrastructure Masterplan) Pertamina C&T 2022-2032.