using Process Plant Project Data Cost

in PERTAMINA for more Precision,

Valid, & Reliable AACE Class 4

Estimation Purpose in Indonesia

FEATURED PAPER

By Tangguh Wijoseno, CCP

Jakarta, Indonesia

Abstract

Lang Factor is Conceptual Estimating Method for estimating Total Plant Cost (TPC) by multiplying a Factor (f) by its Total Equipment Cost (TEC). Hans Lang introduced this Concept in 1947 (70+ years ago). Many things have changed since Hans Lang introduced this Concept, such as Modern construction techniques, computerized design practices, Etc. For its current implementation, the Author needs to research the correlation between TPC and TEC and the most appropriate lang factor range value to be applied in Class 4 Estimation. To address this issue, the Author Collected 92 of PERTAMINA’s Project Data Costs from 2017 to 2022. The range of TPC Value starts from $12.2 million to $1.1 Billion and processes it using Cost Estimating Relationship (CER) and Monte Carlo Simulation. The study’s findings show a very strong correlation between TPC and TEC. The authors chose the 3.00 to 5.33 range as a precise, valid, and reliable range to be utilized as an updated Lang factor that will be used to estimate Class 4 AACE for liquid processing plant costs in Indonesia.

Keywords: Lang Factor, Cost Estimating, Class IV Estimation, Equipment Factor, Top-Down Estimate, Project Screening, Concept Evaluation, Feasibility Study, Cost Estimating Relationship, Montecarlo Simulation.

Introduction

Cost Estimation Philosophy

“A cost estimate is a Compilation of all the potential costs related to the project or effort components that fall within a specified range. An investment choice, project, or activity’s resources must be quantified, budgeted, and valued using the predictive process known as cost estimation. Cost estimation is a method for predicting ambiguous future costs. In that regard, cost estimating minimizes the estimate’s uncertainty, given the scope definition level and quality. An expected and probabilistic cost distribution are desired outcomes of cost estimating. The accuracy of cost estimating is increased using previous reference cost data as a prediction procedure (where applicable).”[1]

“An estimate’s scope and level of information are determined by its intended usage, which also defines its purpose. There are two general uses for cost estimates: (1) to support managers in analyzing projects performance and affordability and the choice of alternative systems and methods, and (2) to facilitate the budgeting process by presenting estimates of the funds required to implement a program. More specific applications for cost estimates include providing data for trade studies, independent reviews, and baseline changes.”[2]

AACE Class Estimation

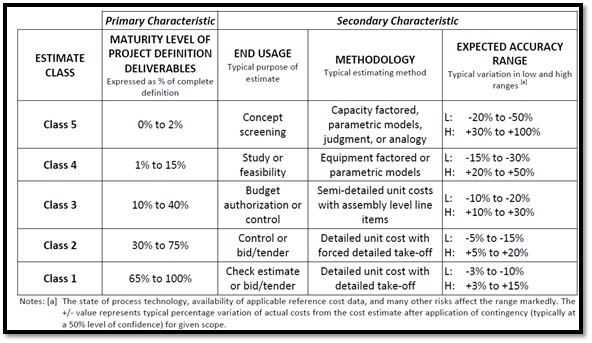

In the Recommended Practice 18R-97 document, AACE International has classified the Cost Estimate Matrix for Process Industries as shown in the table below:

Table 1. Cost Estimate Classification Matrix for Process Industries[3]

Table 1 illustrates typical ranges of accuracy ranges that are associated with the process industries. Depending on the technical and project deliverables (and other variables) and risks associated with each estimate, the accuracy range for any particular estimate is expected to fall into the fields identified (although extreme risks can lead to more comprehensive ranges).[4]

More…

To read entire paper, click here

How to cite this paper: Wijoseno, T. (2023). Modifying The Lang Factor using Process Plant Project Data Cost in PERTAMINA for more Precision, Valid, & Reliable AACE Class 4 Estimation Purpose in Indonesia; PM World Journal, Vol. XII, Issue VI, June. Available online at https://pmworldlibrary.net/wp-content/uploads/2023/05/pmwj130-Jun2023-Wijoseno-modifying-the-lang-factor-for-better-cost-estimates.pdf

About the Author

Tangguh Wijoseno, CCP

Jakarta, Indonesia

![]()

Tangguh Wijoseno, CCP is a Senior Specialist Cost Engineer with twelve (12) years (since 2011 – Present) of experience in an oil and gas refinery and petrochemical development project. He is currently working as a Senior Specialist Cost Engineer at the Indonesian National Oil Company. Having a strong interest in the energy industry (Oil and Gas) along with the spirit of the transition to green energy. Holding a bachelor’s degree in chemical engineering from Universitas Indonesia; he attended a distance learning mentoring course under the supervisory of Dr. Paul D. Giammalvo, CDT, CCE, MScPM, MRICS, GPM-m Senior Technical Advisor, PT Mitratata Citragraha (PTMC/APMX), to attain Certified Cost Professional certification from AACE International.

Tangguh Wijoseno, CCP lives in Jakarta, Indonesia, and can be contacted at tangguh.wijoseno.kpi@gmail.com & tangguh.wijoseno@yahoo.com

[1] AACE International, Recommended Practice No. 46R-11. (2013). Required Skills And Knowledge of Project Cost Estimating, Page 1 of 21, AACE International, Morgantown, WV.

[2] United States Government Accountability Office (2020). GAO Cost Estimating and Assessment Guide, Best Practices for Developing and Managing Program Costs. Page 38.

[3] AACE International, Recommended Practice No. 18R-97. (2013). Cost Estimate Classification System, Page 3 of 10, AACE International, Morgantown, WV.

[4] AACE International, Recommended Practice No. 18R-97. (2013). Cost Estimate Classification System, Page 4 of 10, AACE International, Morgantown, WV.