Evaluating Project Scheduling and Cost Estimating

Processes Against Global “Best-Tested

and Proven” Practices

FEATURED PAPER

By Muhammad Fadhli Zilikram

Jakarta, Indonesia

ABSTRACT

Project overruns, affecting both time and budget, are widespread, with no exception in Indonesia’s downstream oil & gas industry. Poor estimation during scheduling and cost-estimating processes contributes significantly to the failure of projects. The Company has a goal for the projects, which is on time and within budget, but the current condition is still far from expectations. This study aims to find references that companies can use to improve the performance of scheduling and cost-estimating processes. Benchmarking is done by identifying several standards worldwide used, selecting a basis for comparison, assessing each other, and selecting the best reference as the “Best-Tested and Proven” Practice using Multi-Attribute Decision Making (MADM). The result of the analysis found that GAO is the best in the scheduling process and the cost-estimating process. Using the Pareto principle, a priority order has been obtained from the most significant gaps between GAO vs. Company Standards that the Company can refer to minimize work.

Keywords: Scheduling Process, Cost-Estimating Process, Downstream Oil & Gas, Infrastructure Project, Best-Tested and Proven, GAO Schedule Assessment Guide, GAO Cost Estimating & Assessment Guide

INTRODUCTION

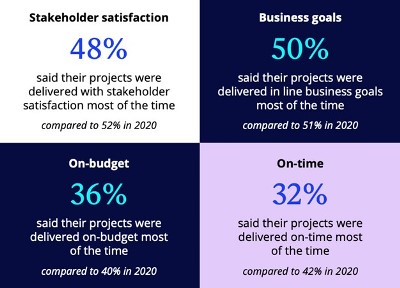

Indonesia oil & gas experiences “56 percent of projects experience a 10 percent cost and overrun schedule, and around 36 percent experience cost and overrun schedule up to 25 percent at 45 projects”[1]. Similarly, Shah notes that “in India, from 1635 government projects, about 35 percent delayed by a large margin and responsible for 65 percent cost overrun”[2]. Likewise, Kearney report that “60 percent of capital projects on oil & gas, chemicals, utilities, metal, and mining, have more than 10 percent overrun on cost and schedules, and nearly a third have more than 25 percent overrun on cost”[3]. The most recent data, KPMG & AIPM found it was getting worse as “in 2022, only around 36 percent of their project on budget and 32 percent on time. Compared in 2020, 40 percent of their project delivered on budget and 42 percent on time”[4]. Therefore, this is challenging for project management to develop credible cost estimates and reliable schedules.

Figure 1 – Project Deliver Performance on KPMG & Australian Institute of Project Management[5]

“The problem of project overruns in the construction industry is a global phenomenon”[6]. Project overrun refers to both schedule and cost overrun. “Schedule overrun means late completion or delivery from the time specified and agreed by all parties of the construction project, while cost overrun means the project completed at a cost higher than what was budgeted”[7]. These two things influence one another and are usually analyzed to obtain the optimum point of both things, as shown in Figure 2.

Project overruns happen for various reasons, which makes the problem complicated and involves many different aspects. In general, Abdulaziz confirms that “major causes of time overrun in Indonesia are design changes, poor labor productivity, inadequate planning, and resource shortages, whereas for cost overrun are material cost increases due to inflation, inaccurate material estimating, and degree of project complexity”[8].

More…

To read entire paper, click here

How to cite this paper: Zilikram, M. F. (2023). Benchmarking Indonesia’s Downstream Oil & Gas Construction: Evaluating Project Scheduling and Cost Estimating Processes Against Global “Best-Tested and Proven” Practices; PM World Journal, Vol. XII, Issue X, October. Available online at https://pmworldlibrary.net/wp-content/uploads/2023/10/pmwj134-Oct2023-Zilikram-Benchmarking-Indonesias-Downstream-Oil-and-Gas-Construction.pdf

Editor’s note: This paper was originally prepared during a 6-month long Graduate-Level Competency Development/Capacity Building Program developed by PT Mitrata Citragraha and led by Dr. Paul D. Giammalvo to prepare candidates for AACE CCP or other Certifications. https://build-project-management-competency.com/our-faqs/

About the Author

Muhammad Fadhli Zilikram

Jakarta, Indonesia

![]()

Muhammad Fadhli Zilikram is an engineer with eight years of professional experience in the oil and gas sectors. Currently, he works at the National Oil Company of Indonesia. During his career, he has an experience as a Maintenance Engineer, Piping Inspector, Tank Inspector, Cost Estimator, Mechanical Engineer, and Project Engineer. He has involved in several projects, including Fuel Terminal, LPG Terminal, Pipeline, Marine Facilities, and other downstream oil & gas projects.

He holds a bachelor’s degree in Mechanical Engineering from Bandung Institute of Technology (ITB) and a certified professional engineer from Diponegoro University. He is attending a distance learning mentoring course under the tutorage of Dr. Paul D. Giammalvo, CDT, CCE, MScPM, MRICS, GPM-m, Senior Technical Advisor (Project Management), PT Mitratata Citragraha (PTMC/APMX), to attain Certified Cost Professional certification from AACE International.

Fadhli lives in Jakarta, Indonesia, and can be contacted at muhammad.zilikram@gmail.com.

[1] Wisnugroho, J. (2020). Indonesia Oil & Gas Cost Estimating vs International “Best-Tested and Proven” Practices – A Benchmarking Study; PM World Journal, Vol. IX, Issue II, February.

[2] Shah, V. A. (2021). Cost and Time Overrun in Various Construction Projects: A Review; Psychology And Education.

[3] Excellence in capital projects: A goal yet to be achieved – Article – Kearney. (2017, February 27). Kearney. Retrieved from: https://www.kearney.com/industry/energy/article/-/insights/excellence-in-capital-projects-a-goal-yet-to-be-achieved.

[4] KPMG & AIPM. (2022, November). The state of project management in Australia 2022.

[5] Ibid

[6] Sambasivan, M., & Soon, Y. W. (2007). Causes and effects of delays in Malaysian construction industry. International Journal of Project Management, 25(5), 517-526. Retrieved from: https://doi.org/10.1016/j.ijproman.2006.11.007.

[7] Mukuka, M., Aigbavboa, C., & Thwala, W. (2015). Effects of construction projects schedule overruns: A case of the Gauteng province, South Africa. Procedia Manufacturing, 3, 1690-1695. Retrieved from: https://doi.org/10.1016/j.promfg.2015.07.989

[8] Seddeeq, A. B., Assaf, S., Abdallah, A., & Hassanain, M. A. (2019). Time and cost overrun in the Saudi Arabian oil and gas construction industry. Buildings, 9(2), 41. Retrieved from: https://doi.org/10.3390/buildings9020041.