and artificial intelligence in industrial systems programs

FEATURED PAPER

By Dr Lalamani Budeli

South Africa

Abstract

Machine learning fits mathematical models to data to derive insights or make predictions. A feature is a numeric representation of an aspect of raw data and features sit between data and models in the machine learning pipeline. In the 21st century, the use of software systems to improve the performance of engineering systems intelligence has realized major improvements in industry. In the modern industrial engineering system, the compatibility of equipment to communicate with other equipment using standard industrial protocol and sharing data is a requirement for manufacturers throughout the world. The improving need for industrial machine intelligence requires machine learning algorithms that use input data that gets processed to create outputs. The level of intelligence required from engineering systems require incorporation of data science process which are agile, following iterative methodology to deliver predictive analytics solutions and intelligent applications efficiently.

Engineering process control and instrumentation equipment, networks, controllers, and databases produce a lot of data that requires learning algorithms to improve machine intelligence through feature engineering and its role in enhancing data in machine learning. Engineered features that enhance training provide information that better differentiates the patterns in the data required domain expertise for sound and productive decisions. The purpose of this paper is to demonstrate how the application of feature engineering and artificial intelligence can help companies fully realize the benefits of their analytics program.

Keywords: Feature engineering, industrial systems, project and programs

Introduction

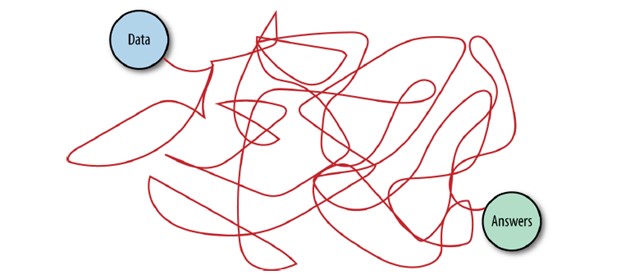

In the 20th century, the process and system approach gained momentum in both science and engineering. A lot of systems and process models were designed to resolve industrial problems. Systems thinking focuses on how the whole system works together while a process is a smaller part of the larger system. A system maintains its existence through the mutual interaction of its parts with a sequence of activities, to keep the coherence of the parts and ensure the required functions. A process on the other hand, is a sequence of activities intended to produce a particular result. This means that inside the system, there are processes. Engineering processes and systems produce a lot of data that if it is interpreted accurately can assist the industry to improve efficiency, resolve problems quickly and save money. Part of the complexity of engineered systems research derives from integrating factors that represent their use in products or services factoring in their impacts on manufacturing efficiency, the environment, society, or the human body, as appropriate to the system chosen. Therefore, consideration of the complex interactions and effects of the system’s operation is factored into the development, integration, and ongoing management of the components. Engineering process and systems produce a lot of data and the figure below indicates the path between data and answers.

Figure 1 Path Between Data and Answers (Zheng & Casari ,2018:4)

As an emergent technological advancement, machine learning algorithms use some input data to produce results. In most systems, the data available might not be enough for designing a good machine learning model which requires feature engineering. Electrical and computer engineers work at the forefront of technological innovation, contributing to the design, development, testing, and manufacturing processes for new generations of devices and equipment. The process of creating new features from raw data is important to increase the predictive power of the learning algorithm. Engineered features should capture additional information that is not easily apparent in the original feature set. The process of selecting the key subset of features to reduce the dimensionality of the training problem.

More…

To read entire paper, click here

How to cite this paper: Budeli, L. (2021). Application of feature engineering and artificial intelligence in industrial systems programs, PM World Journal, Vol. X, Issue II, February. Available online at https://pmworldlibrary.net/wp-content/uploads/2021/02/pmwj102-Feb2021-Budeli-Feature-engineering-and-AI-in-industrial-systems-programs2.pdf

About the Author

Dr Lalamani Budeli

South Africa

![]()

Dr Lalamani Budeli obtained his degree in Electrical Engineering at the Vaal University (VUT), BSc honors in Engineering Technology Management at University of Pretoria (UP), Master in engineering development and Management at North West University (NWU), Master of business administration at Regent Business School (RBS) and a Doctor of Philosophy in Engineering Development and Management at North West University (NWU), Potchefstroom, South Africa. Currently, he is a managing director of BLIT, an engineering, research, and project management company based in South Africa.

His research interests include project portfolio management, agile project management, plant life cycle management, advanced systems analytics, project early warning system, and the use of artificial intelligence in project management. Currently, he is spending most of the time on research that is looking at the development of system and application that uses the latest technology like block chain, internet of things (IoT), Big data, and artificial intelligence. Lalamani Budeli can be contacted at budelil@blit.co.za.

To view other works by Dr. Budeli, visit his author showcase in the PM World Library at https://pmworldlibrary.net/authors/lalamani-budeli/